Field inspections are up against many of the same challenges and possibly more than what field service team must deal with. Maintenance, safety, regulatory, and warranty inspections all benefit from field inspectors who are experienced, knowledgeable, and up to date with the standards they are evaluating equipment and systems against. Experienced inspectors are not always available.

Training and up-skilling a growing percentage of less experienced inspectors while reducing costs is a common inspection pain point. Reliance on paper-based inspection checklists is another issue as field inspectors may not have the most current standards in the moment they need them. And then, there is the concern for consistently achieving inspection results that meet expectations. According to Quality Magazine, “most manual inspection tasks typically exhibit error rates of 20-30 percent.”

Field inspection by definition is a geographically distributed responsibility and it’s required across a broad range of industries and use cases. Service Council research notes that one in five field service engineers concentrate on inspections. It’s not easy or cost effective to frequently gather these inspectors for training sessions and updates. So how can you ensure your field inspections are up to standards, being efficiently conducted and effectively managed without negatively impacting employee experience?

New visual technologies, such as augmented reality are opening the door for addressing these challenges and going beyond to digitally transform field inspection. Interactive 3D and augmented reality visual resources add contextual benefits that help field inspectors stay up to date with procedures and regulations, accurately evaluate against standards, and more quickly complete field inspections.

Remote expert real-time inspection support with augmented reality is a new opportunity for field inspection. The process works when a field inspector connects with a remote expert over the phone and points their standard rear-facing smartphone or tablet’s camera at the system or device being evaluated. The CareAR® Assist app takes advantage of computer vision technology to “map” the space. This creates a visual foundation that enables the remote expert to draw graphical guidance overlayed within the field inspectors’ field of view. This graphical direction “sticks” in place even if the field inspector moves their smartphone!

Now you have contextual visual awareness for a remote inspection expert as if he or she were there in person. Graphical guidance is tuned for every situation, especially for the “that shouldn’t be there” situations. Less experienced field inspectors and contractors can be up-skilled “on demand” to improve inspection quality and consistency while adding a confidence boost with real-time guidance and verification.

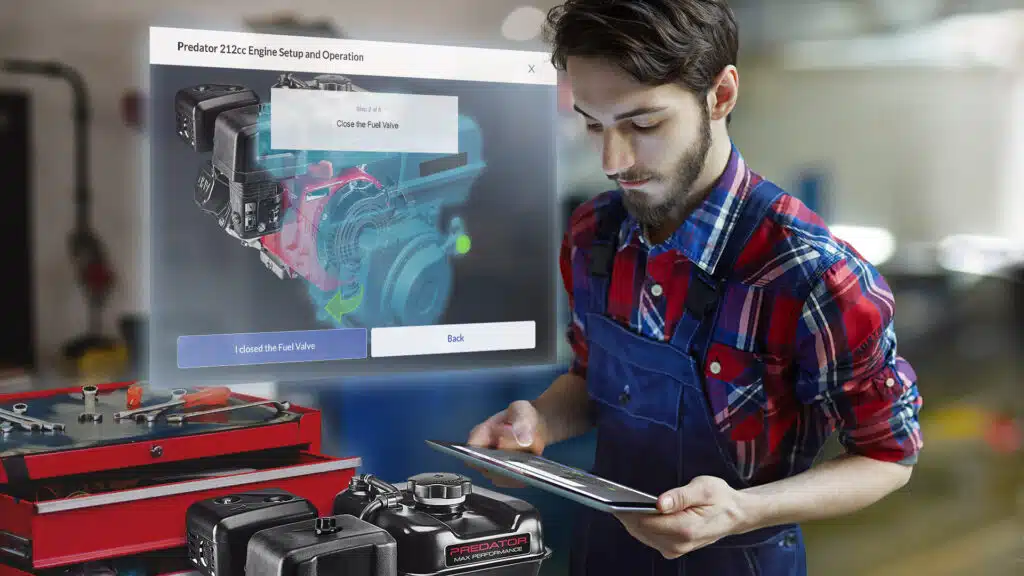

New visual technologies can also improve field inspector performance with step-by-step self-direction. Paper-based inspection guidance can be replaced with a digital inspection flow that visually engages inspectors. Use of an interactive 3D model enables users to manipulate the digital twin of a device being inspected within a user’s smartphone or tablet filed of view.

With CareAR® Instruct, users can interactively flip, spin, and zoom into areas of a 3D model for a visual perspective that might be difficult or impossible to do especially with heavy equipment or when safety considerations are involved. Step-by-step inspection self-guidance with digital twins visually engages users with detail far beyond a CAD drawing or even a video.

With CareAR® Instruct, users can interactively flip, spin, and zoom into areas of a 3D model for a visual perspective that might be difficult or impossible to do especially with heavy equipment or when safety considerations are involved. Step-by-step inspection self-guidance with digital twins visually engages users with detail far beyond a CAD drawing or even a video.

Augmented reality can take filed inspection self-guidance to even greater heights. A CareAR Instruct session with augmented reality enables inspectors to point their smartphone at the device being inspected and see “hotspot” graphics overlayed in their field of view to guide focus. A hotspot click reveals step guidance along with graphics or animations overlayed on the actual device to visually direct action such as remove the right panel in the proper sequence. The inspector can then be digitally directed to proceed through subsequent steps.

But how do you know the inspector was on point with their actions? New AI-fueled computer vision technology has arrived to help provide this automated verification. CareAR Instruct can be deployed with state detection which works to verify if an action has been completed appropriately of not. For example, a field inspection procedure may require that a lever be switched to an off position to ensure that a safe inspection procedure can commence. CareAR step-by-step guidance will use AI-based computer vision to verify of that action has occurred as the inspector points their smartphone at that the object with the lever.

A key benefit is the contextual self-guidance that the inspector experiences. Direction and verification overlayed on the actual target of an inspection make it easier to comprehend and accomplish what actually needs to be done using a new form of automation. Immediate digital feedback optimizes performance as inspectors are guided with visual engagement laser focused on the integrity of completing each inspection step.

Field inspection remote assistance and self-guidance using augmented reality presents new opportunities for process change. Field inspection quality, consistency and cost saving can now be achieved with remote inspection expert real-time guidance and self-directed step-by-step digital inspection procedure flows.

To get started, look for field inspections with mechanical elements, safety challenges and equipment complexity as procedures to target. Outline what defines success when deploying visual inspection technology for your inspectors. It’s not necessarily a single measure, such as cost savings. Boosting inspection quality, avoiding regulatory fines, and increasing equipment uptime are additional metrics that can be targeted for measuring project success.

Think about moving toward digital inspection procedures to overcome your paper-based challenges. The use of visual technologies can introduce process shifting inspection flows such as such as cost effectively implementing customer self-guided pre-inspections to streamline onsite evaluations or automated inspection step capture to take manual effort out of regulatory compliance.

CareAR is changing the way field inspectors accomplish their evaluations with innovative visual technologies that take advantage of the standard handheld devices that inspectors use every day. The CareAR Service Experience Management (SXM) platform powers field inspections with self-guidance and remote assist support with efficiency and effectiveness benefits while improving the field inspector experience.

Download the Augmented Reality for Next generation Field Inspection white paper to find out more.